- B-465, Industrial Estate 2nd Gate, Karnataka, India

- info@magtoolsindia.com

- Mon - Sat 10.00 - 18.00

A magnetic coolant filter is an essential component in grinding applications, particularly in industries where precision and cleanliness are critical. Here’s a brief overview of its purpose and benefits:

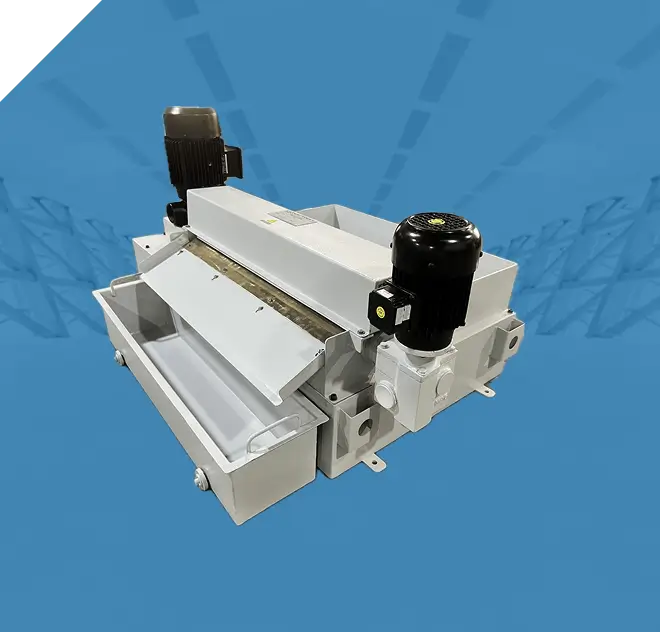

Mag Tool’s Magnetic Coolant Filter are designed for filtering coolant oils contaminated with ferrous materials. These equipments are light weight, compact design, and can be easily installed.

Mag Tools is a leading manufacturer of coolant filtration systems, specializing in high-quality products that are designed to effectively remove contaminants from industrial coolant fluids.

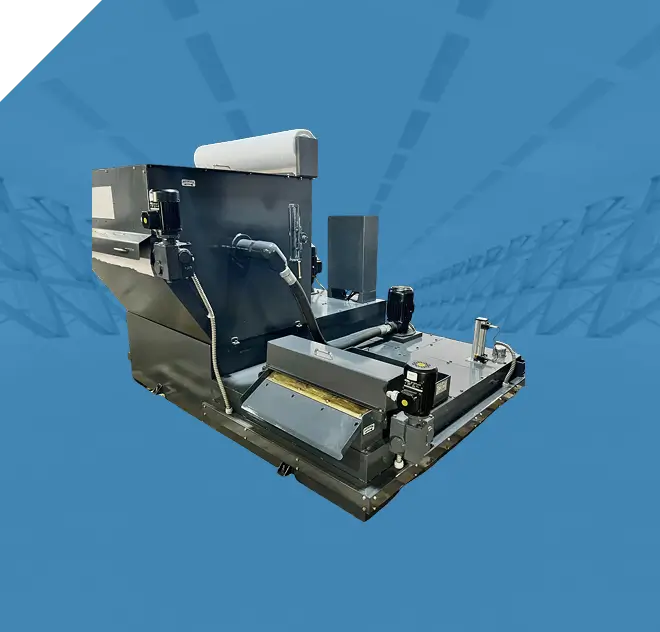

Mag Tools Paper band filter unit is fabricated in steel. This entire unit is fixed on a coolant tank with a pump to supply clean coolant back to the grinding machine.

Fully automated compact band coolant filters are easy to operate and provides cost effective solution for filtration. These systems are specially designed for space efficiency and require only 20% of the space as compared to other conventional paper band filters.

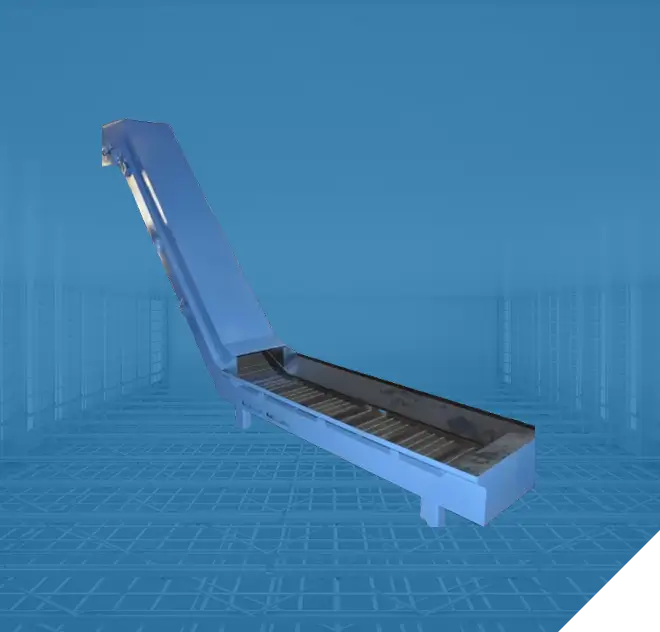

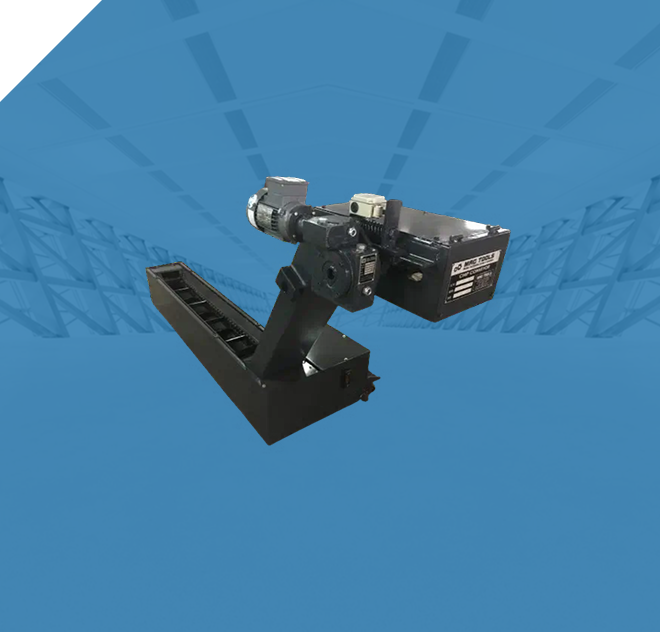

MAG TOOLS Hinged steel belt chip conveyors are been specially designed keeping in mind the hazards that are normally encountered with conventional chips and swarf Conveyors.

FINE – Light and sharp chips generated from gear shaves, Gear Hobbing machines, Spline cutting machines, SPM’s deep hole drilling machines, broaching machines, Press shops and Heat treatment shops coming with large amount of coolant tend to escape with the coolant and cause damage to the pump and effects surface finish.

Chip Centrifuge becomes progressively more important in today’s machine shops. Environmental laws limit the maximum residual coolant that can be retained in transported swarf and economically, reclaiming expensive coolant and the increased sales value of relatively dry chips are of vital importance.

MAG TOOLS new ALUMINIUM CHIP CONVEYOR CUM DRUM FILTER was developed and performance – proven by Bunri Industries, Ltd., Japan. The ALUMINIUM CHIP CONVEYOR CUM DRUM FILTER offers the machine Tools industry a highly effective method for the difficult task of separating aluminum chips, fines and turnings from flowing coolant. It employs a new and unique concept that incorporates a drag conveyor with Drum (rolling) filters. Numerous advantages include:

Our hydrocyclone coolant filter is an advanced and highly efficient solution for filtering coolant during machining processes.

Our hydrocyclone coolant filter utilizes the principle of centrifugal force to separate solid particles from the coolant. It consists of a cyclonic unit, which creates a swirling motion within the coolant, allowing the heavier particles to be continuously discharged through the bottom while the cleaner coolant is extracted from the top.

A simple and effective way to clean water soluble coolant from floating tramp oil. Disc type oil skimmers, drum type magnetic oil skimmers.

MAG TOOLS now has available small, cost effective oil skimmers for removing tramp oil from machine tool coolant tank. The MAG TOOLS wheel skimmer (WS) effectively removes floating tramp oil from water soluble coolants. In its magnetic version (MWS) it will even remove dispersed ferrous particles from the coolant.

Mag Tools filter paper rolls are designed for high-quality filtration applications across various industries. Manufactured using premium-grade materials, these filter paper rolls offer excellent retention capabilities, consistent porosity, and superior chemical resistance. Ideal for laboratory, industrial, and environmental testing needs, Mag Tools filter paper rolls provide reliable performance for separating solids from liquids, sample preparation, and analytical processes.

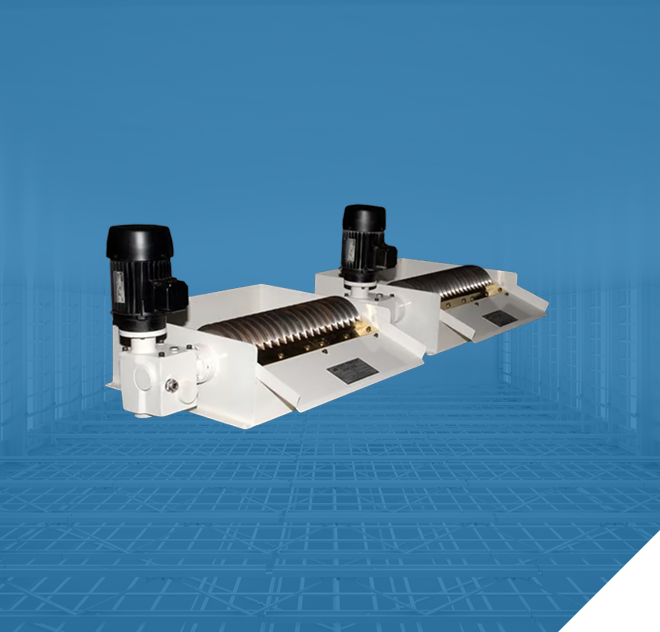

Mag tools scraper conveyors are suitable for handling short powdered chips and sludges from the coolant effectively from high chips producing machines like SPMs etc.. Available in width 50 mm to 1500 mm width. Safety tripping arrangement is a standard features..